Why LEDA For CNC Machining?

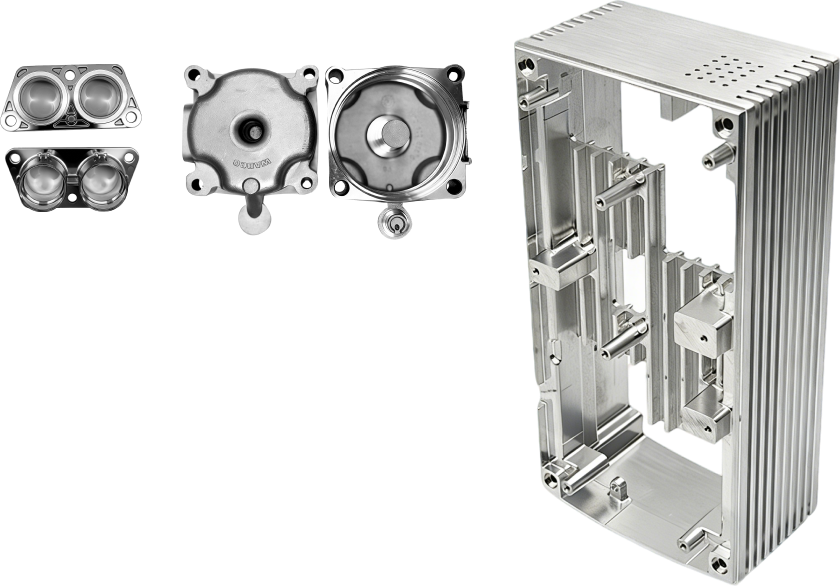

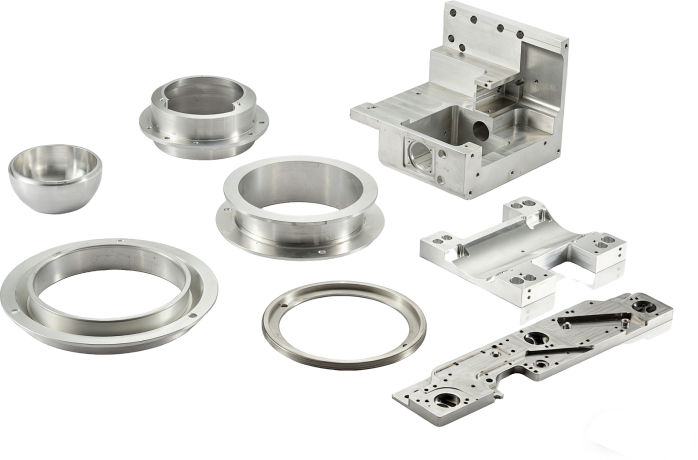

Core Capabilities

Micron-level Precision Control

Achieves Consistent Machining With Standard Tolerances Of ±0.01mm And High-precision Capabilities Up To ±0.005mm Or Tighter, Supported By Advanced Equipment And Temperature Control.

Full-process Inspection Support

In-process And Final Inspection Are Enabled By CMMs, Surface Testers, And Profilometers To Verify Critical Dimensions And GD&T.

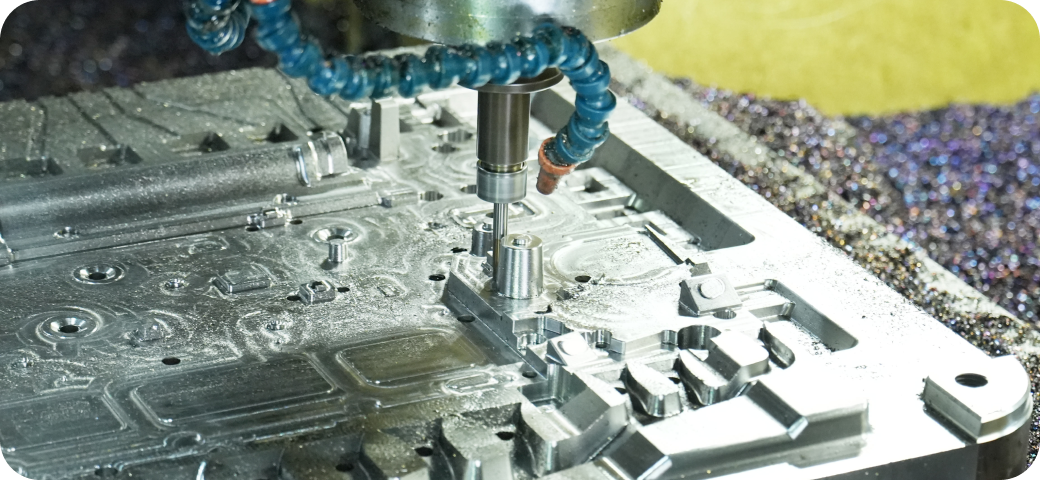

Multi-axis Precision Machining

Equipped With 3-, 4-, And 5-axis Machining Centers For High-accuracy Finishing Of Complex Surfaces, Angled Holes, And Profiles In A Single Setup.

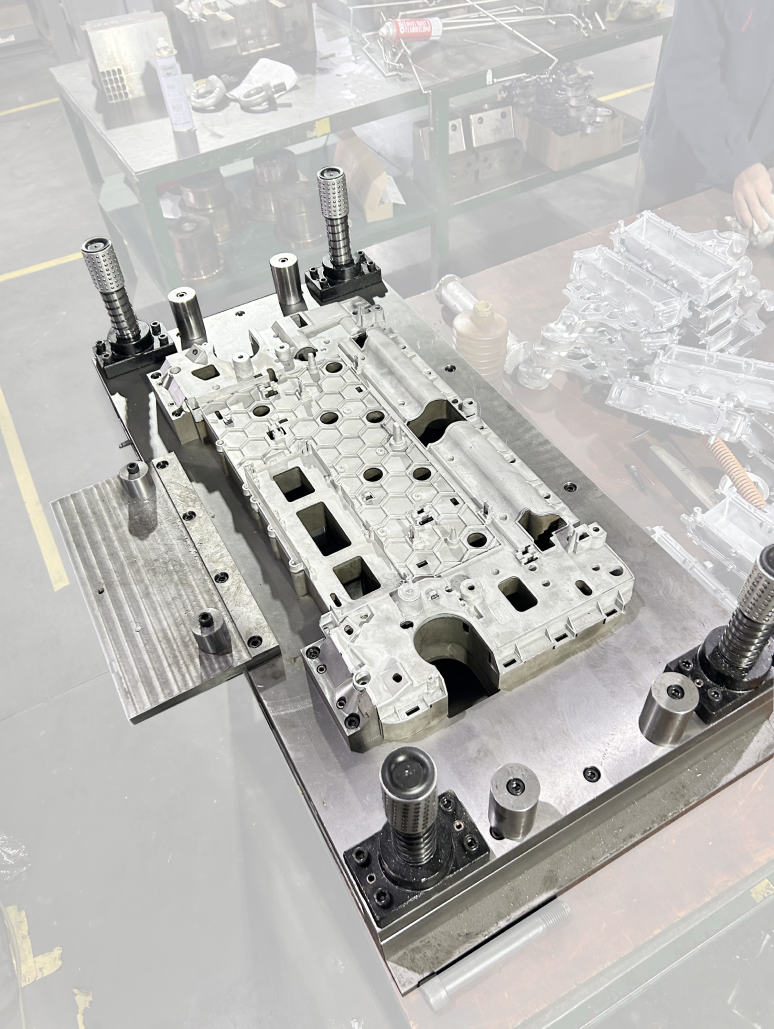

Oversized Part Machining

Capable Of Machining Large Structural Components And Molds Over 5 Meters In Length And Several Tons In Weight Using Gantry Mills.

Expert In Difficult-to-machine Materials

Specializes In The Stable Machining And Quality Control Of Hard, Gummy Materials Like Titanium, Inconel, Tool Steels, And Engineering Ceramics.

CNC Machining Center An Intelligent, Automated Precision Machining Device Controlled By Computer Programs And Integrating Multiple Cutting Functions. It Processes Raw Materials Such As Metal Or Engineering Plastics Through High-speed Rotating Tools Performing Milling, Drilling, Tapping, And Other Operations. Within A Single Setup, It Directly And Precisely Manufactures Complex-shaped, Dimensionally Accurate Parts.

Get In Touch

Ready to start your next manufacturing project? Our team is here to help.