Deconstructing NPI Success from an R&D Perspective

Why Do Camera and Radar Modules Require Special Encapsulation Processes?

Automotive camera and radar modules operate in extremely harsh environments. They need to withstand continuous vibration, extreme temperature variations, humidity erosion, and various physical impacts throughout the vehicle’s lifecycle. Traditional encapsulation methods often struggle to maintain stable performance over the long term under these conditions.

More importantly, these modules contain numerous precision electronic components internally, requiring hermetic sealing via welding processes to prevent the intrusion of contaminants like moisture and dust. Welding quality is directly related to the long-term reliability of the module, and the characteristics of the encapsulation material are a key factor determining the welding outcome.

Building an Indestructible Foundation for Vision and Perception Systems

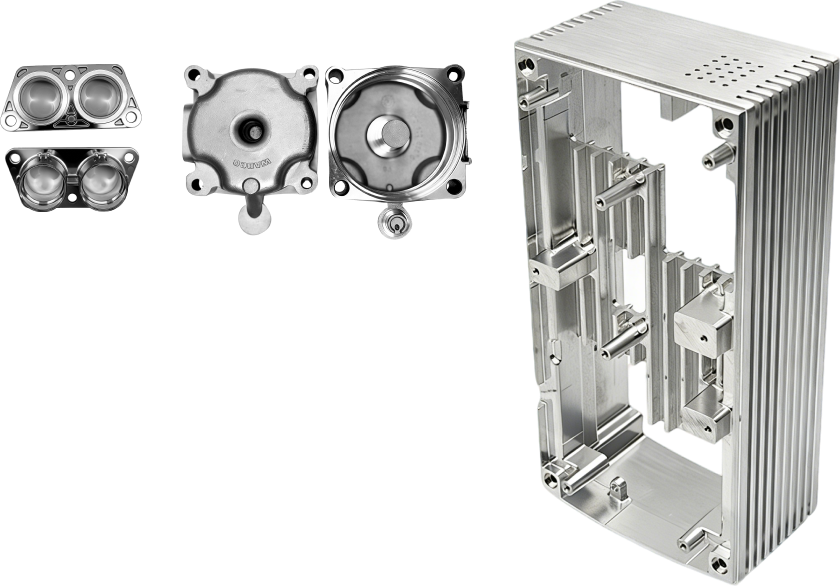

In the wave of automotive intelligence, Advanced Driver-Assistance Systems (ADAS) and autonomous driving features are rapidly becoming standard vehicle configurations. As the “eyes” and “ears” of the vehicle, the reliability of camera and radar modules directly determines the performance of the entire intelligent driving system. In the manufacturing of these precision sensors, the choice of encapsulation structure is crucial, and the adoption of pure aluminum forging is emerging as the common choice for leading companies in the industry.

Pure Aluminum vs. Die-Cast Aluminum: Why Pure Aluminum is Superior?

In the field of automotive sensor encapsulation, pure aluminum (1000 series) demonstrates significant advantages over traditional die-cast aluminum.

Pure aluminum boasts extremely high material purity (Al content ≥ 99.0%), meaning it exhibits excellent thermal conductivity and fluidity during welding. This effectively reduces defects like porosity, cracks, and cold welds. This welding reliability is paramount for camera and radar modules that require long-term stable operation.

In contrast, die-cast aluminum contains alloying elements like silicon and copper. These elements can form irregular intermetallic compounds, which easily become stress concentration points during welding, reducing the air tightness and mechanical strength of the weld joint.

Practical Application Cases: Solutions Provided for Huawei, Hesai, and Others

LEDA’s pure aluminum forging process has been successfully applied to products from several industry leaders:

Huawei Visual System Module: The pure aluminum forged housing provided for its ADAS camera resolved long-standing industry challenges with welding airtightness. By using 1000 series aluminum and optimized welding parameters, the welding pass rate increased to over 99.9%, significantly reducing field failure rates.

Hesai LiDAR Protective Structure: Addressing the dual high requirements for heat dissipation and airtightness in LiDAR, LEDA developed a dedicated pure aluminum forged protective cover. Its excellent thermal conductivity ensures stable LiDAR operation in high-temperature environments, while the robust structure effectively protects internal precision optical components.

Core Advantages of the Pure Aluminum Forging Process

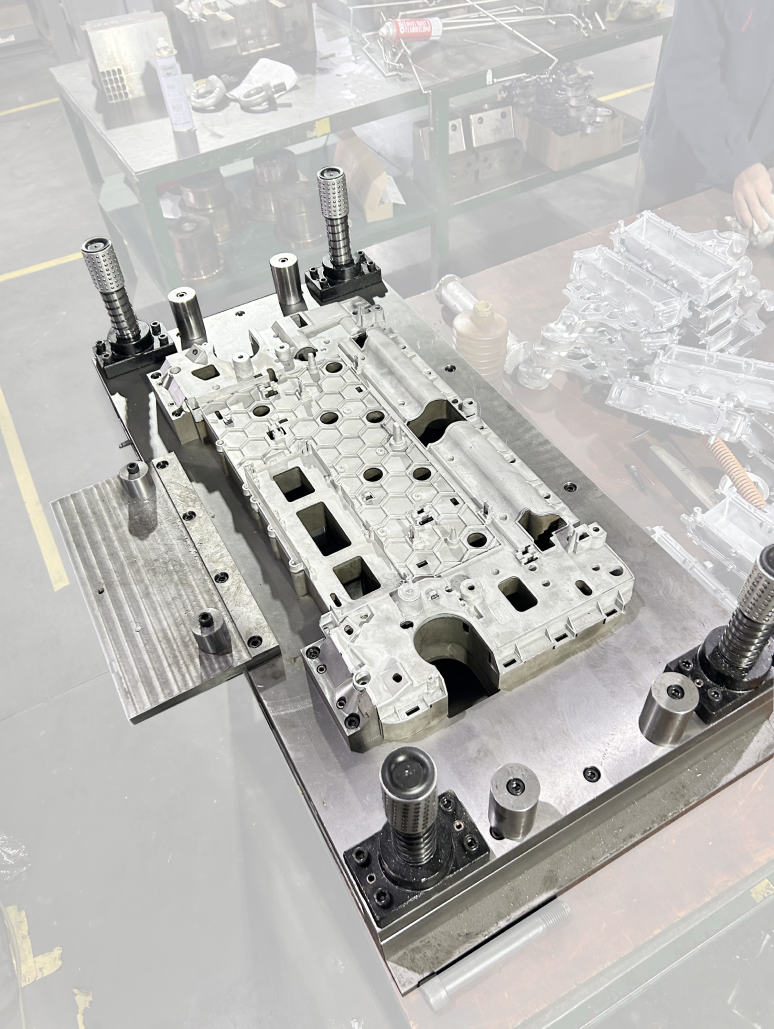

The cold forging process used by LEDA Intelligent Automation is a near-net-shape technology. It plastically deforms the aluminum material resulting in an extremely dense metal flow line structure. This provides multi-level sealing protection.

Pure aluminum itself has excellent thermal conductivity (~237 W/m·K). Cold-forged components rapidly conduct internal heat to external structures, preventing electronic component failure due to overheating.

The cold forging process induces work hardening, increasing strength by 10%-15%. This means pure aluminum forgings can better protect internal precision electronics from vibration and impact.

LEDA’s “One Mold, Four Cavities” technology increases material utilization to over 80%, far exceeding traditional CNC machining. This highly efficient method significantly reduces unit cost.

Future Outlook

As automotive intelligence continues to advance, requirements for sensor module reliability will become increasingly stringent. The pure aluminum forging process, with its exceptional sealing, thermal management, and mechanical protection capabilities, is positioned as the preferred encapsulation solution.

LEDA Intelligent Automation is ready to collaborate with industry partners to promote the wider application of this advanced technology.