State-of-the-Art Inspection Equipment & Scientific Management System

To ensure that every component meets the most stringent dimensional, material, and surface finish standards, we have established a comprehensive inspection capability covering macro to micro, and geometry to material properties. This is supported by a systematic, traceable equipment management system, providing a solid foundation for consistent quality excellence.

Advanced Inspection Equipment Portfolio

Our quality lab is equipped with multi-dimensional, high-precision measuring instruments, guaranteeing accurate measurement and verification at every stage from raw material to finished product.

3D Dimensional Metrology

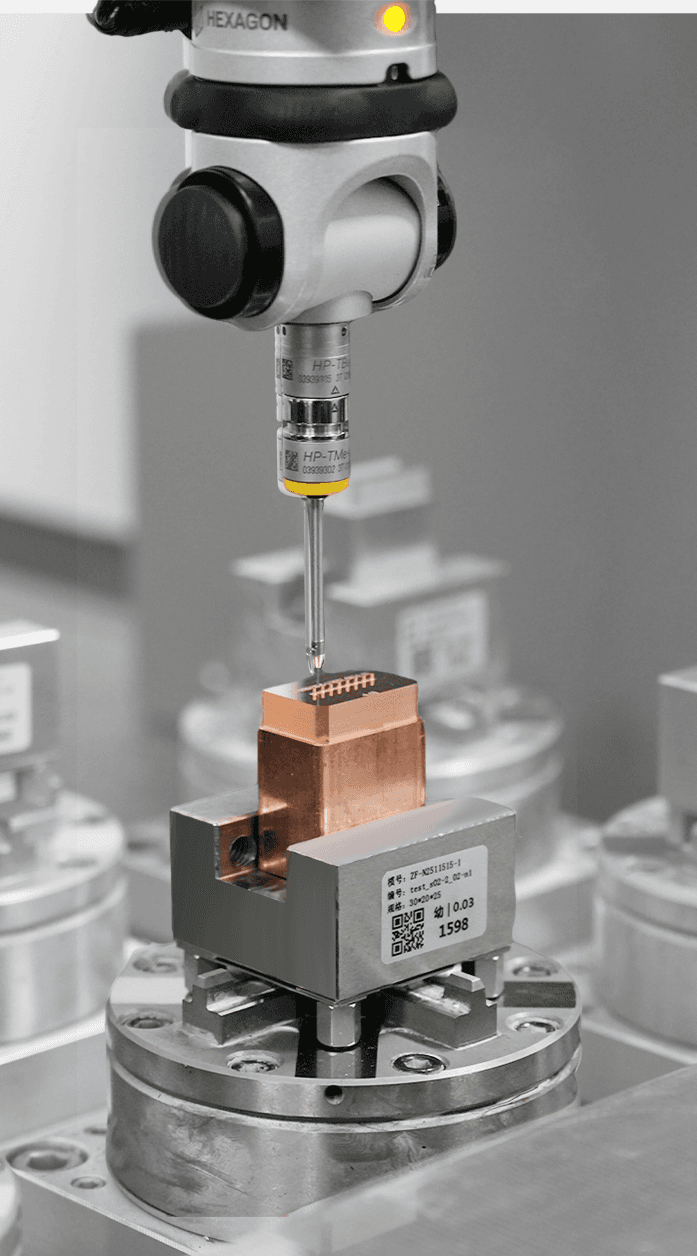

High-Precision Coordinate Measuring Machines: Multiple CMMs from industry leaders like Hexagon, Zeiss, Nikon, and Mitutoyo enable highly accurate and repeatable measurement of complex 3D geometries, form, and position tolerances. They are the core for mold validation and critical dimension inspection.

2D & Rapid Optical Inspection

Automated Vision Measuring Systems: Enable fast, non-contact, and precise measurement of 2D dimensions and contours, significantly improving inspection throughput for small, flat parts.

Optical Comparators / Toolmaker’s Microscopes: Used for profile comparison, angle measurement, and rapid first-article inspection, providing intuitive visual overlay of part profiles.

Microscopic Observation & Analysis

Digital Video Microscopes: Used to examine surface microstructure, machining texture, micro-defects, and assembly conditions. They are vital tools for failure analysis and process improvement.

Precision Gauge Systems

Master Gauge Sets: Comprehensive sets of ring gauges, plug gauges, and thread gauges for fast and reliable in-process and final inspection.

Height Gauges / Height Masters: Provide accurate measurement of height, flatness, and center distances.

Calibration-Grade Gauge Blocks & Pin Gauges: Serve as the primary standard for dimensional traceability, used for daily equipment verification and calibration.

Precision Hand-Held Instruments

A full assortment of micrometers, calipers, and digital indicators: Covering a wide range from quick handheld checks to precise measurement, providing reliable tools for production lines and inspectors.

Surface & Material Property Analysis

Form & Roughness Measuring Instruments: Integrated systems capable of measuring roundness, cylindricity, contour, and surface roughness, providing a complete shape and texture evaluation in one setup.

X-Ray Fluorescence Spectrometer: Used for rapid, non-destructive material composition verification, ensuring raw materials and alloy grades strictly comply with specifications, preventing material misuse at the source.

Coating Thickness Gauges: Precisely measure the thickness of platings and coatings on parts, ensuring compliance with corrosion resistance and functional requirements.

Rigorous Equipment Management & Calibration System

Advanced equipment requires rigorous management to maintain its long-term accuracy and reliability. We implement a scientific strategy of “Dedicated Responsible Personnel & Combined Internal-External Calibration Control.”

Dedicated Equipment & Personnel Management

Responsible Engineer System: Each core piece of equipment (e.g., CMM, XRF, Form Tester) is assigned to a specifically trained engineer responsible for its daily operation, preventative maintenance, and data management.

Standardized Operating Procedures: Detailed SOPs are established for all equipment to ensure consistency in measurement methods and the repeatability of results.

Full-Lifecycle Calibration & Verification

We have established a complete traceability chain, ensuring all measurement results are traceable to national/international standards.

External Professional Calibration: All critical equipment and master standards (e.g., CMMs, gauge blocks, master gauges) are periodically sent to accredited calibration laboratories possessing CNAS or equivalent international recognition for calibration. Calibration certificates are archived, ensuring the authority and legitimacy of our measurement traceability.

Internal Periodic Verification & Daily Checks: Between external calibration cycles, we perform daily quick checks, weekly, or monthly accuracy verifications using externally calibrated master artifacts. Daily repeatability and stability checks are performed upon equipment startup to confirm operational readiness.

Digitalization & Traceability

Equipment & Calibration Database: An electronic management system tracks each device’s model, serial number, location, last/next calibration dates, certificates, and historical data.

Automated Alerts: The system provides automatic reminders before calibration is due, ensuring no equipment is used outside its valid calibration period.

Traceable Results: Every inspection report can be traced back to the specific equipment used and its calibration status, fulfilling the stringent measurement traceability requirements of quality management systems like IATF 16949 and AS9100.

We firmly believe that investment in and meticulous management of our measurement capabilities is the most fundamental commitment to product quality. This comprehensive inspection system and rigorous management framework are not only the technical cornerstone for delivering zero-defect products but also the foundation for building long-term trust with our customers. Please feel free to inquire or schedule a visit to our quality laboratory for a firsthand demonstration.

Certificate of Honor