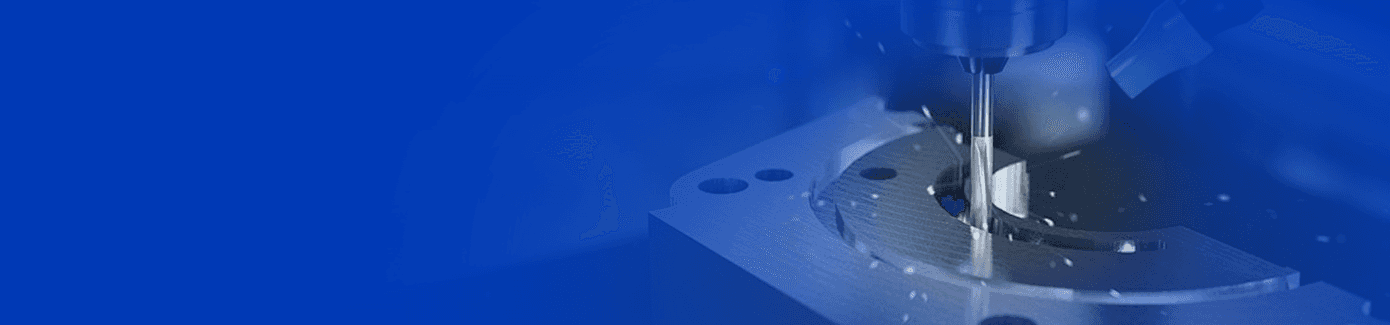

Precision Plastic Mold Making

The mold is the mother of the part. We build high-quality molds for over a million cycles, especially for medical and electronics. Using mold flow analysis, conformal cooling, and premium steels, we ensure stable, efficient production of perfect parts.

Why LEDA for Plastic Mold Making?

Built for High-Precision Products – We focus on manufacturing ultra-high-precision, long-life injection molds required by the medical, optical, and electronics industries.

Combination of Science and Experience – We use mold flow analysis to guide design and employ techniques like hardened steels and conformal cooling to enhance mold performance and production efficiency.

Ensures Production Stability – A superior mold is the foundation of consistent quality. The molds we deliver are a reliable guarantee for your mass production success.

Core Capabilities

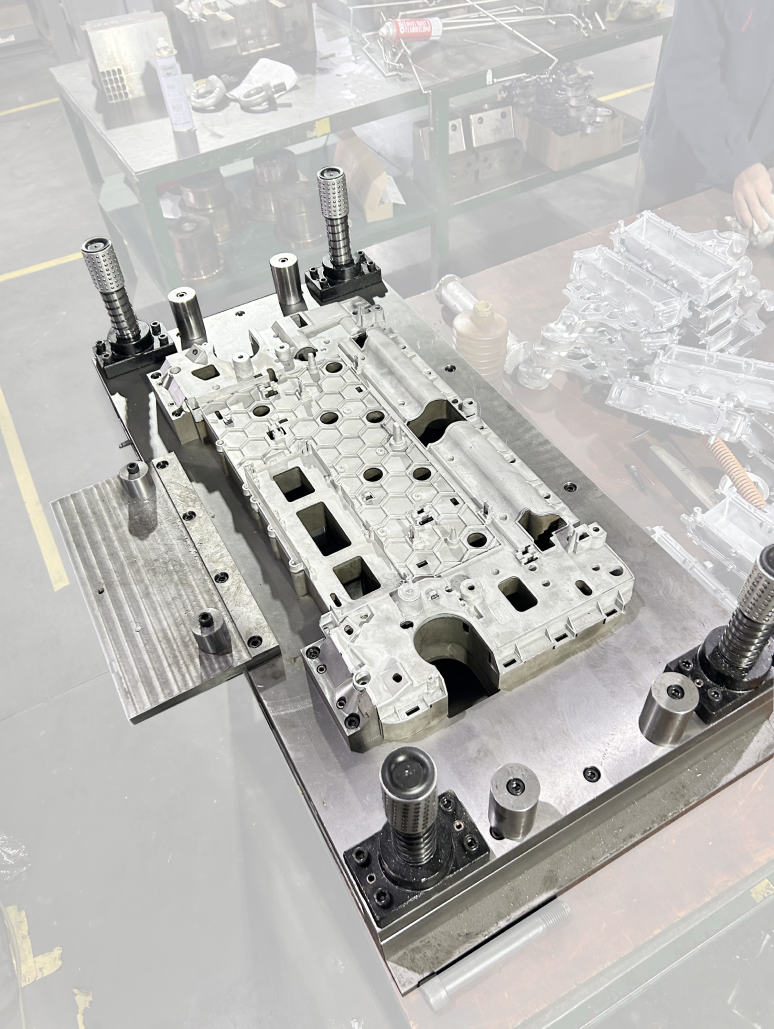

High-Cavity, Long-Life Mold Design & Build

Specializes in molds with over 1 million shot life, using high-hardness, high-polishability steels.

Mold Flow Analysis & Thermal Management

Employs CAE software for filling, cooling, and warpage analysis, and uses conformal cooling for optimized cycle time and quality.

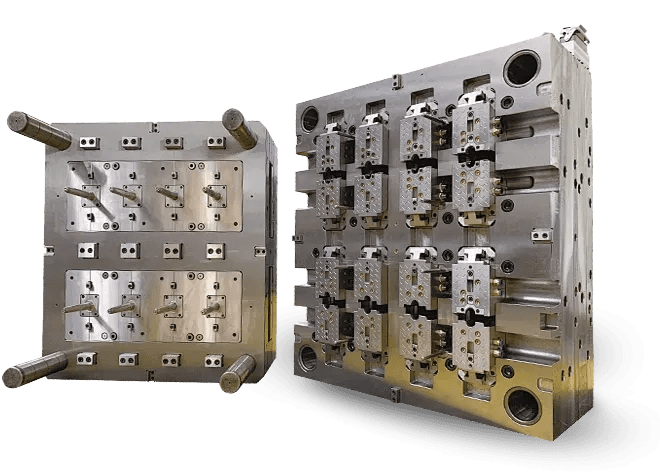

Multi-Cavity & Stack Mold Technology

Designs and builds high-cavity-count molds or stack molds to maximize output per shot and minimize unit cost.

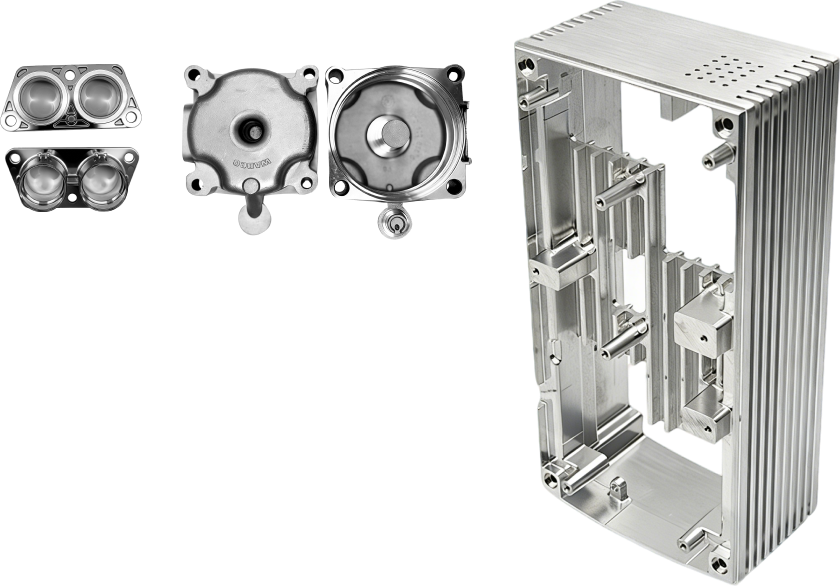

Micro-Features & High-Gloss Surface Machining

Capable of machining micro-gears, micro-channels, lens arrays, and achieving SPI A1 mirror finishes.

General Tolerances for Orientation & Form Features (Metals)

| Part Feature Length (in) | 0 to 12″ | 12″ to 24″ | 24″ to 36″ | 36″ to 60″ | > 60″ |

|---|---|---|---|---|---|

| Orientation & Form Tolerance (in) | 0.004″ | 0.008″ | 0.016″ | 0.031″ | 0.063″ |

| Angularity Tolerance | 0.5° | 0.5° | 1.0° | 1.0° | 1.0° |

| Angularity Tolerance | 0.5° | 0.5° | 1.0° | 1.0° | 1.0° |

| Angularity Tolerance | 0.5° | 0.5° | 1.0° | 1.0° | 1.0° |

Download the form

Quality Standards/Material Selection

Let's Build Something Great, Together

Processing Site