Q&A Center

General Company & Capabilities

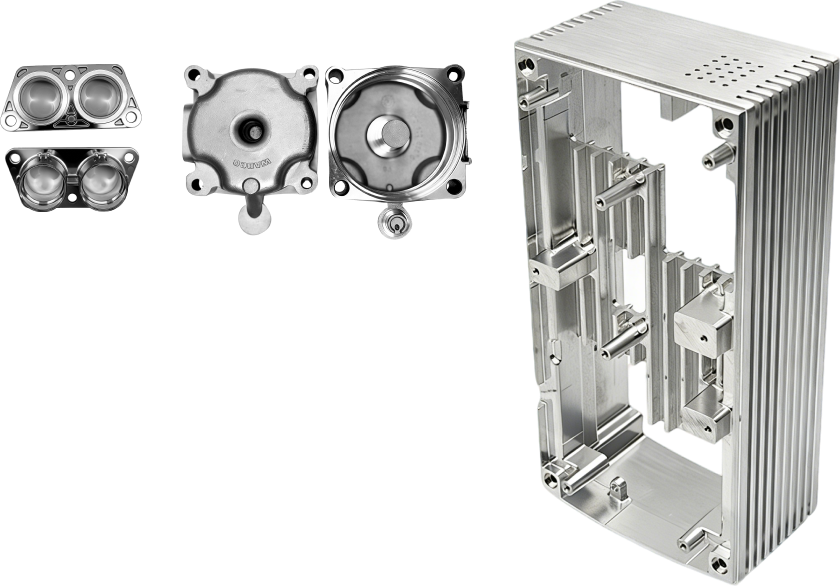

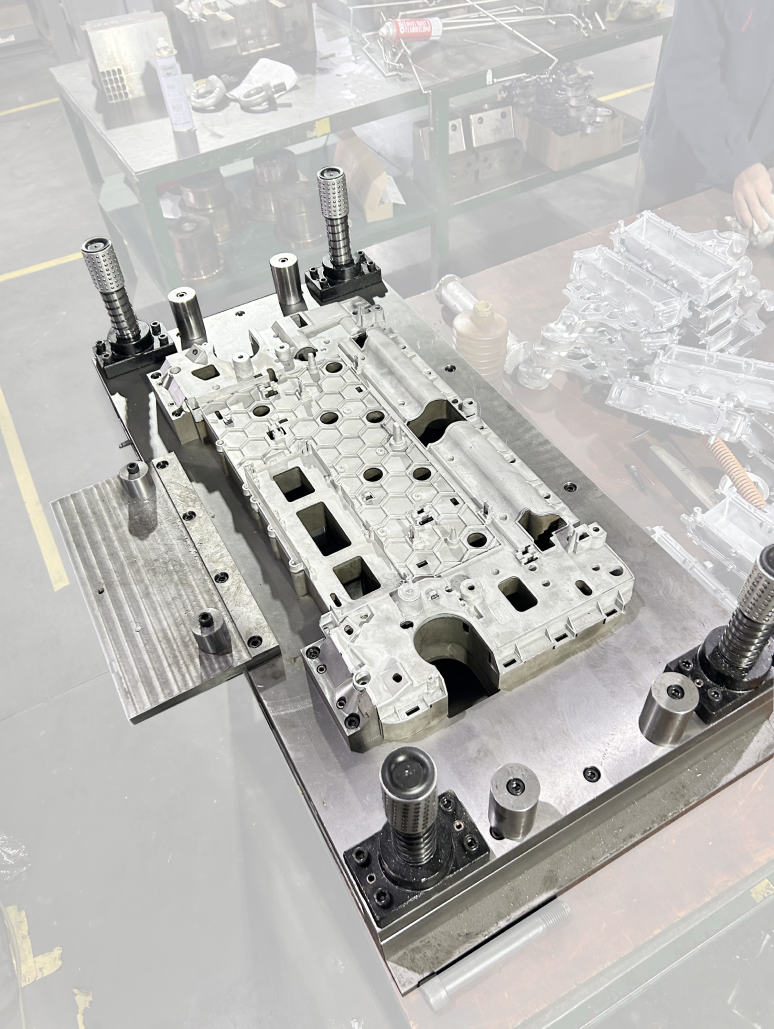

LEDA Precision is a full-service contract manufacturer specializing in high-precision components. We integrate advanced processes including CNC machining, plastic injection molding, die casting, metal stamping, and additive manufacturing (3D printing) with comprehensive in-house tooling design and fabrication. Our 20-year focus is on serving industries where precision, quality, and reliability are non-negotiable.

We have extensive experience serving the aerospace, medical device, automotive, robotics, and consumer electronics industries. Our quality management systems and precision standards are designed to meet the stringent requirements of these sectors.

We operate a certified Quality Management System compliant with IATF 16949 (Automotive) and ISO 9001 standards. Our processes are also aligned with the rigorous framework of AS9100 (Aerospace), and we can support audits and provide necessary documentation for regulated industries.

Quoting & Project Initiation

For the most accurate and rapid quote, please provide:

3D CAD Model: Preferred formats are STEP or IGES.

2D Drawing: A detailed PDF drawing with critical dimensions, GD&T, material specification, surface finish requirements, and part number/revision.

Quantity & Application: Your target volumes (prototype, pilot-run, production) and brief description of the part’s function.

Special Requirements: Any specific standards, certifications, or post-processing needs.

For standard RFQs, we aim to provide a comprehensive quotation with DFM (Design for Manufacturability) feedback within 24-48 hours. Complex projects requiring detailed process engineering may take 2-3 business days.

Yes. Our engineering team automatically conducts a DFM review with every quotation. We identify potential production challenges, suggest optimizations for cost and performance, and provide clear alternatives, all at no obligation.

Design & Engineering Support

Absolutely. Our engineering services extend to concept development and design assistance. We can help translate your idea into a manufacturable design, ensuring it is optimized for performance and cost from the start.

Our standard tolerances are process-specific and are detailed in our publicly available Technical Standards sheets for each service (CNC Machining, Injection Molding, etc.). These can be found on our website’s resources section. We routinely hold tolerances much tighter than industry standards.

Yes, we offer reverse engineering services. Using high-precision 3D scanning and measurement equipment, we can create a digital model and drawing from your sample, which can then be used for quotation and production.

Materials & Finishing

We have access to a vast network of material suppliers and can source hundreds of metals, plastics, and alloys. Common materials include various grades of aluminum, stainless steel, brass, titanium, PEEK, Ultem, ABS, Nylon, and more. Contact us for specific material requests.

es. Certificates of Conformity (CoC) and Material Test Reports (MTRs)/Certification (Mill Certs) are available and provided with your shipment for traceability and quality assurance, as specified.

We provide a full range of services:

Surface Finishes: Bead blasting, anodizing (Type II/III), powder coating, plating (Ni, Zn, Cr, etc.), passivation, polishing.

Secondary Operations: CNC post-machining, tapping, heat treatment, sonic welding, assembly, and packaging.

Manufacturing & Quality

Quality is integrated into every step. Our protocol includes:

Incoming Material Inspection

First Article Inspection (FAI): Full-dimensional report with CMM data.

In-Process Quality Checks (IPQC)

Final Audit Inspection before shipment. We follow a Stage-Gated Verification process where no part proceeds without verification.

Our quality lab is equipped with state-of-the-art metrology, including CMMs (Hexagon, Zeiss), 3D scanners, optical comparators, surface roughness testers, and XRF spectrometers. All equipment is under a strict calibration program.

Customer satisfaction is our priority. We guarantee all parts meet the specifications agreed upon in the purchase order. In the rare event of a non-conformance, please contact your Project Manager immediately. We will conduct a thorough investigation and work with you on a swift resolution, which may include rework, replacement, or credit.

Ordering & Logistics

Standard terms for new clients are a 50% deposit upon order confirmation, with the 50% balance due prior to shipment. For established customers, net terms can be arranged. We accept bank transfer (T/T) and major credit cards.

We have partnerships with major global carriers (DHL, FedEx, UPS) and freight forwarders. We can handle everything from export documentation to door-to-door delivery. Shipping costs are calculated and confirmed before your order is finalized.

Lead times vary significantly based on process, part complexity, and quantity. General guidelines:

CNC Machining & 3D Printing: 1-3 weeks.

Injection Molding / Die Casting: 4-8 weeks (including mold fabrication).

High-Volume Stamping: 8-12 weeks (including die fabrication).

We offer expedited services—inquire for rush options.

Confidentiality & Partnership

IP protection is fundamental. We are willing to sign a mutual Non-Disclosure Agreement (NDA) before any technical discussion. All customer data is stored on secure servers, and access is strictly controlled. We treat your designs as our most trusted secret.

Unless otherwise stated in a separate agreement, the customer retains 100% ownership of all tooling (molds, dies, fixtures) paid for. We safely store your tooling and maintain it per agreed schedules, ready for your next production run.

This is our preferred model. We see ourselves as an extension of your engineering and manufacturing team. We invest in understanding your long-term goals to provide strategic support, from NPI (New Product Introduction) through to full-scale production and lifecycle management.