An established industry principle holds that up to 80% of a product's ultimate cost is locked in during the design phase. This means a minor, forward-looking design optimization early on can yield benefits in cost savings, quality improvement, and cycle time reduction that are tens or even hundreds of times greater than incremental improvements made on the production floor.

DFM (Design for Manufacturability) is not a constraint on your creativity; it is the discipline that gives your ideas viable, profitable wings.

The Core Value of DFM: Why Are 80% of Costs Decided by Design?

In product development, a widely validated rule states: up to 80% of a product's total final cost is determined during its design stage. This figure is not an exaggeration; it reveals the most leveraged decision point in the entire value chain from concept to market.

The key to understanding this lies in recognizing that costs are not merely incurred on purchase orders or production work orders—they are "pre-set" by a series of fundamental, early-stage design choices.

How Does Design "Lock In" Cost?

- Material & Process Path Dependency:

The materials you select and the manufacturing processes you decide upon directly define the baseline for your supply chain, capital equipment investment, and processing cycle times. This forms the "hard framework" of cost. - The Multiplier Effect of Complexity & Precision:

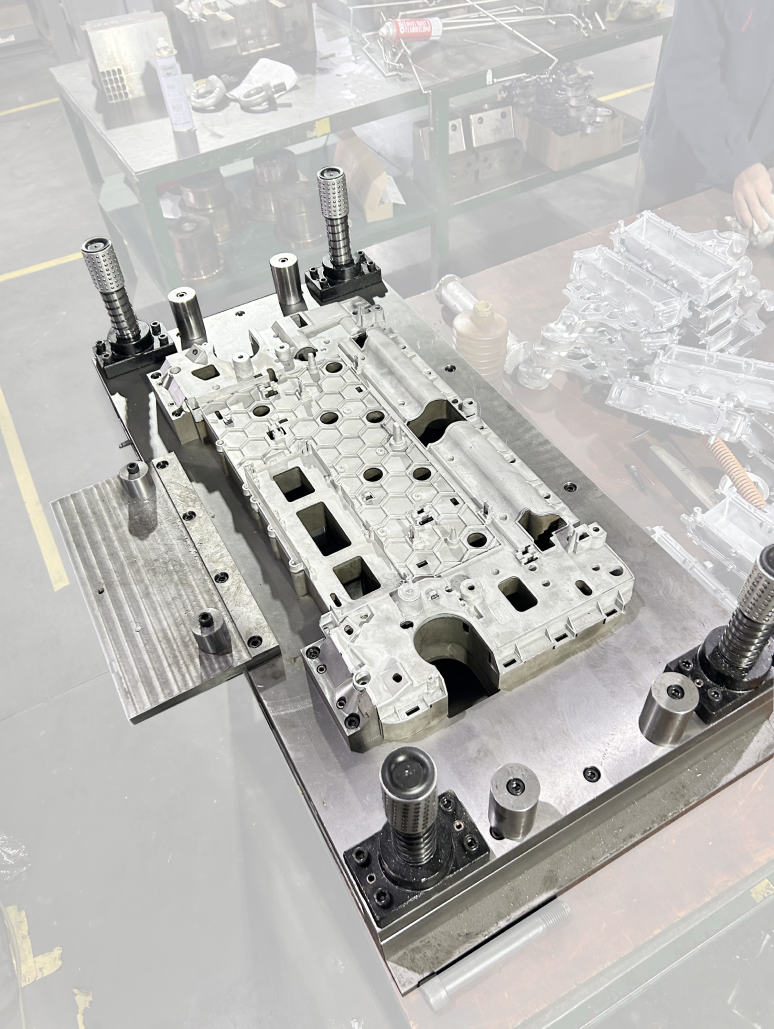

Every non-standard curvature, excessively tight tolerance, or additional assembly step is magnified during manufacturing, translating into more machining time, more expensive tooling, and lower yield rates. Complexity is a cost multiplier. - The Irreversible Commitment of Molds & Tooling:

For processes like injection molding or die casting, once tooling manufacture begins, most of its cost is already incurred. Design changes requiring mold modifications are far more costly than adjusting lines on a drawing. - Setting Supply Chain & Procureability:

The procurement cost, lead time, and supply chain risk for a highly custom part are essentially predetermined the moment the design is finalized.

The Cost of Change: Studies show that if a problem is identified and corrected during the design phase, the cost factor is 1. If corrected during prototyping, it might become 10. If discovered on the mass production line, the correction cost can soar to a factor of 1000.

At Leda, our DFM analysis provides you with precisely this kind of "manufacturing lens." It makes hidden costs visible, adjustable, and controllable before they become reality.

Why is DFM So Critical?

Collaborate with Leda to secure competitive advantage from the earliest design stages.

Traditional DFM often stops at answering the question, "Can this design be made?" At Leda, we hold ourselves to a higher standard: we are committed to answering, "How can it be made in the optimal way?"

Our Four Pillars of "Efficiently Manufacturable":

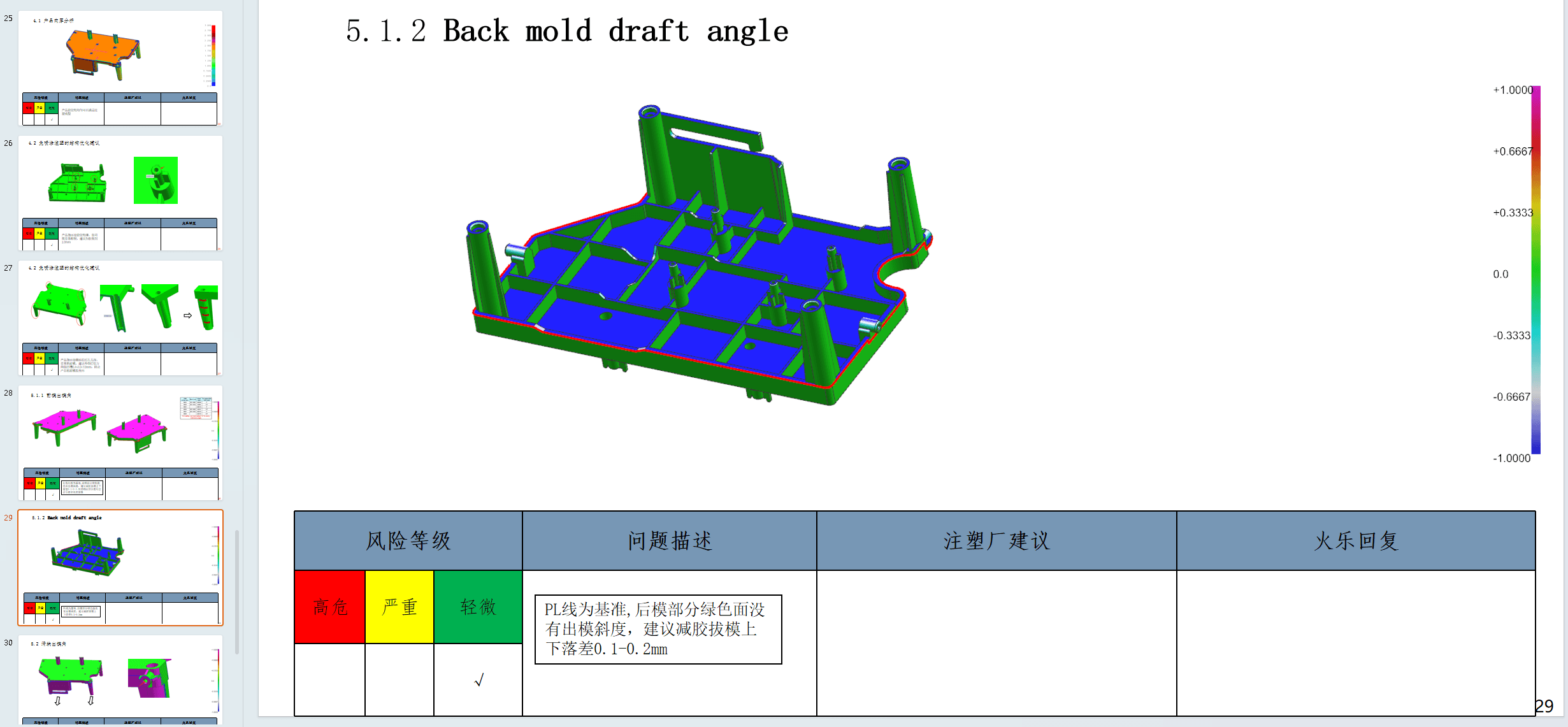

- Predictability: Utilize tools like mold flow analysis and machining simulation to predict issues (short shots, warpage) before manufacturing begins.

- Scalability: Evaluating if a design can transition smoothly from prototype to mass production (e.g., adding guidesfor automated assembly).

- Affordability: Performing "cost-driver analysis" to optimize expensive features for the best balance between performance and cost.

- Sustainability: Factoring in efficiency to reduce material waste and energy consumption.

A Simple Comparison

"This deep-pocket part can be machined, but it will require a custom extended-length tool and result in very long cycle times."

"We recommend reducing the depth of this pocket by 20% or adding a relief hole at the bottom. This allows the use of standard tooling, reduces machining time by 65%, eliminates quality risks, and lowers total cost by 40%."

Quality is Built In Through Design

Traditionally, quality control is seen as an end-of-line activity. At Leda, our philosophy is that true quality cannot be "inspected into" a product; it must be "designed and manufactured into" it.

How Does Leda Achieve "Quality Upfront"?

- Failure Prevention-Driven Design Reviews: Employing FMEA (Failure Mode and Effects Analysis) to systematically challenge the design (e.g., Will this thin wall short shot? Will this sharp corner crack?).

- Designing for Manufacturing Process Robustness: Optimizing designs to be forgiving of inevitable process fluctuations (material batch differences, tool wear).

- Design as Data, Data as Control: Critical dimensions are directly linked to SPC systems and automated inspection equipment.

Cost is Defined by Design: TCO Perspective

Our focus extends beyond the unit price of a component to its Total Cost of Ownership (TCO). This encompasses mold/tooling investment, production yield, assembly efficiency, maintenance costs, and end-of-life disposal.

A seemingly attractive low unit price may hide substantial mold investment, poor production yield, or complex assembly processes. We provide data-driven insights to transparently analyze and optimize the total lifecycle cost.

Leda DFM Service Workflow

From File Upload to Production Release, we guide you through every step.

Stage 1: Instant Analysis & Preliminary Feedback (Within Hours)

Stage 2: In-Depth Engineering Review (1-3 Business Days)

Stage 3: Optimization & Design Freeze (3-7 Business Days)

Stage 4: Data Handover & Production Readiness

Design Guides & Resources

Download our comprehensive guides to master manufacturing-oriented design principles.

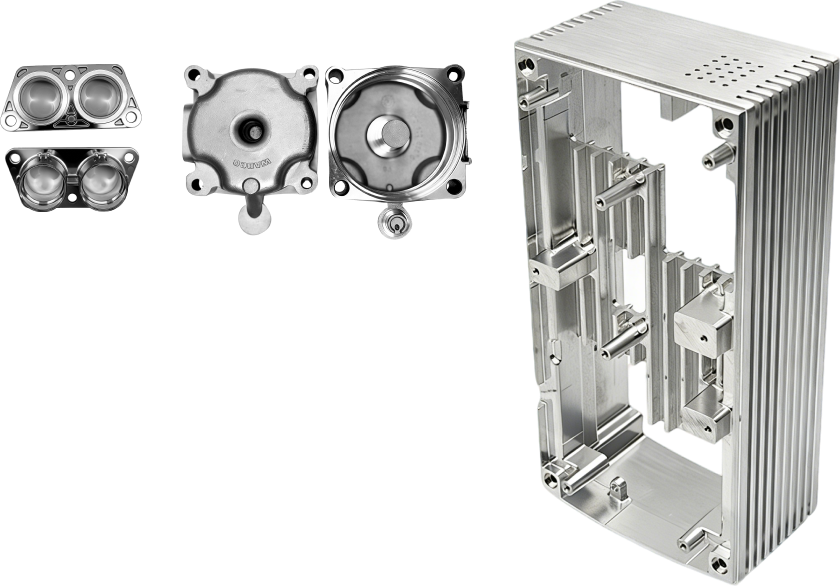

CNC Machining Design Guide

Move beyond "what can be made" to "how to make it better, faster, and more economically." Learn to reduce machining difficulty, enhance rigidity, and simplify assembly.

Download Guide (PDF)Injection Molding Design Guide

Achieve synergy between product design and mold engineering. Learn to avoid sink marks, simplify mold structure, and ensure production stability.

Download Guide (PDF)Die Casting Design Guide

Avoid common defects and reduce costs. Covers material selection (Al, Mg, Zn) and golden rules like uniform wall thickness and rib design.

Download Guide (PDF)Sheet Metal Stamping & Bending

Avoid cracking at bend lines, compensate for springback, and simplify tooling structure for better material utilization.

Download Guide (PDF)3D Printing Design Guide

A complete workflow from process selection to innovative structural design and post-processing.

Download Guide (PDF)

.png)

.png)