We firmly believe that the most effective cost control happens during product design.

Our engineers engage early in the concept and design phases, providing in-depth Design for Manufacturability and Assembly analysis.

We help optimize part geometry, tolerances, materials, and assembly methods to eliminate design flaws that could lead to expensive mold modifications, production inefficiencies, and low yields later.

Preventing one design change is worth far more than any unit price reduction in production—this is core to how we help lock in your costs and accelerate time-to-market.

Early-Stage Collaboration, Preventing Costly Changes

Inefficient communication and disjointed workflows are hidden costs.

Our digital platform enables transparent, end-to-end collaboration—from instant quoting and real-time design reviews to live order tracking and centralized document management.

This drastically reduces the delays, misunderstandings, and rework caused by communication gaps and version errors. It allows your project management to be more focused and efficient, freeing your team from tedious follow-ups to concentrate on higher-value innovation.

Digital Collaboration: Eliminating Hidden Administrative Waste

As your direct manufacturing partner, we leverage our long-term material purchasing volume, strategic supplier network, and integrated in-house process chain to consolidate advantages for you.

This means you gain access to stable, high-quality supplies—from specialty materials to standard components—at more competitive prices.

We are not just a manufacturer, but an extension and stabilizer of your supply chain, translating economies of scale directly into your cost advantage and supply security.

Scale & Integrated Supply Chain Leverage

Unstable quality is a silent profit killer, causing line stoppages, sorting, returns, and reputation damage.

Through our IATF 16949/ISO 13485 certified systems, Statistical Process Control, and full-process traceability, we ensure extreme process stability and part consistency.

We deliver not just conforming parts, but the certainty of “zero-defect” and the trust of “skip-lot” inspection, eliminating the massive hidden costs associated with quality control, rework, aftersales, and brand risk for you.

Quality Stability: Eradicating the Biggest Hidden Cost

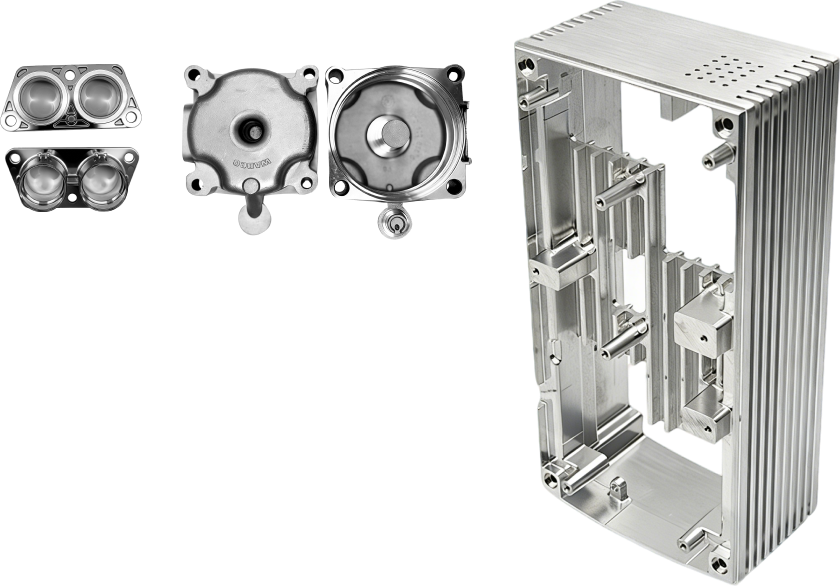

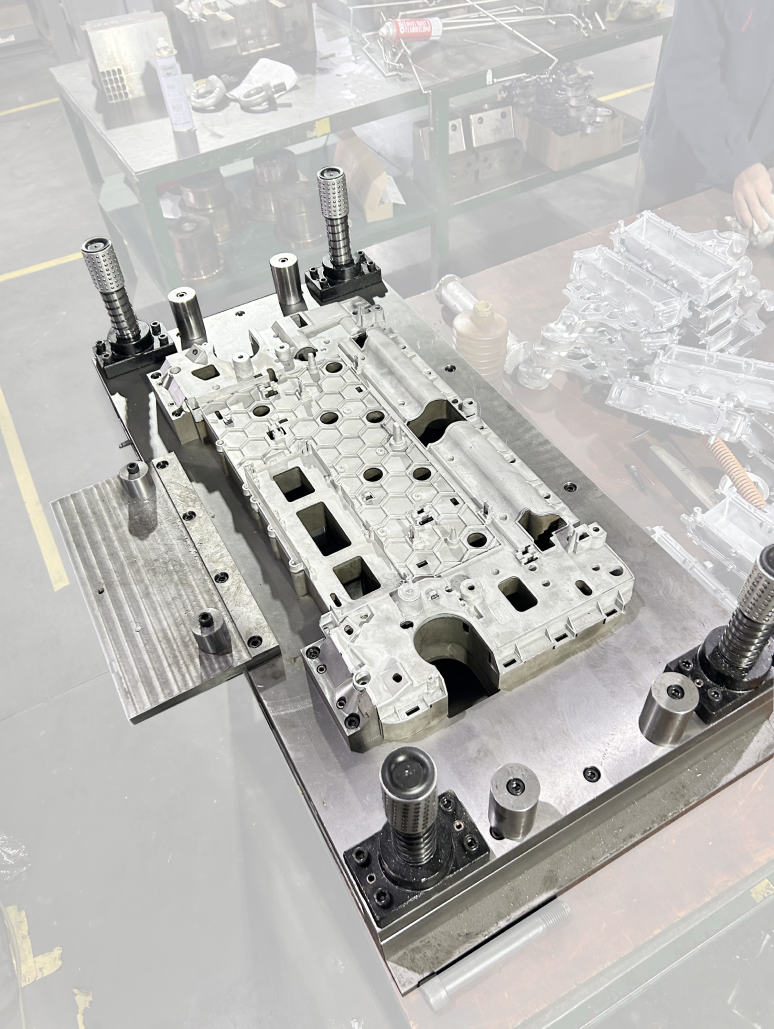

LEDA is a direct manufacturer with ten core process capabilities in-house.

The entire workflow—from design and tooling to machining and assembly—is completed within our own facilities, with no intermediary markups or information loss. You work directly with the manufacturing experts who have final technical and cost-control authority.

This results in a more transparent cost structure, faster decision-making, and every dollar of your investment translating directly into product value, ensuring you receive the most competitive direct cost.